Accurate gas leak detection not only saves money, it saves lives.

MedGas carries out gas leak detection analysis for various clients. Their extensive experience with medical gas delivery helps them target areas that are at most risk of gas leaks. MedGas uses high accuracy gauges, leak detection fluids for specific gases and also employs ultrasonic gas leak detection systems that can pick up most gas leaks behind walls and in ceiling spaces. Ultrasonic gas leak detection systems can detect gas leaks in noisy areas such as plant rooms or compressor rooms in hospitals.

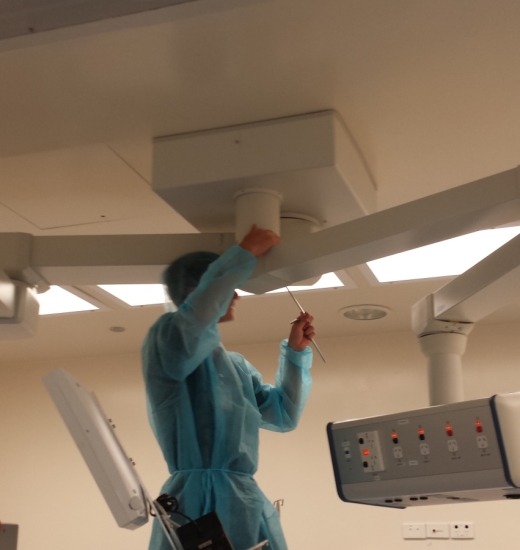

MedGas regularly tests areas at risk of gas leaks such as operating theatre pendants. These are used to provide anaesthesia and all the necessary services and equipment connection facilities in operating theatres, delivery rooms for and surgical purposes. From ZSUs (Zone Service Units) or AVSUs (Area Valve Service Units) medical gases are piped through wards or medical facilities to the terminal units or outlets. These outlets may be recessed into the wall or bed head, housed in a MSP (Medical Services Panel) or in a pendant (normally suspended from the ceiling or wall) that can be moved to supply services to various parts or the room. The terminal units are all gas specific and will only accept the appropriate probe for that gas. MedGas ensures that all mechanical joints, and anywhere that air brakes are connected, are regularly monitored and tested for gas leaks.

$$

Regular gas leak detection means savings on gas purchasing and eliminates dangerous hazards. Roughly speaking, air consists of about 79 percent nitrogen and other gases and about 21 percent oxygen. When the O2 density is increased above 25% most non-flammable material will burn vigorously.

Hospitals have separate pipelines for 100% oxygen and for air, no mixtures being allowed in the pipelines. An oxygen blender is a mixing device connected to the outlets that permits the mix of oxygen with compressed air so health professionals can achieve a controlled oxygen-air mix suitable for each individual patient. Some models of blenders discharge approximately 5 litres of gas a minute into the atmosphere, 24/7.

A medical oxygen G size cylinder costs around $85.00 and contains 8000 litres of oxygen. In a large healthcare facility there can be 1000 or more oxygen wall outlets. If 10% of wall outlets have a 1 litre per minute leak, or blenders exhaust oxygen while connected, then 100 litres/minute or 6000 litres/hour of gas are wastefully emitted. That equates to 144,000 litres of gas per day and 52,560,000 litres per year of leaked gases: 6570 bottles annually. At a cost of $85.00 per bottle, a grand total of

$558,450.00 of gas is wasted per year.

Even if the only gas leak in the entire site is 1 litre/minute this would still equate to 65.7 bottles per year or $5,584.50.